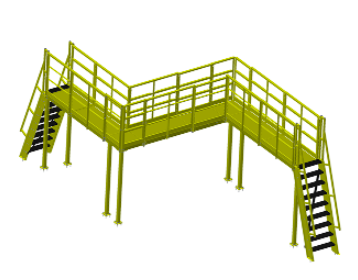

Bluff’s goal is to provide you with conveyor crossover solutions that maximize the efficiency of operations and minimize the possibility of potential injuries by keeping personnel safe.

FEATURES AND BENEFITS:- Welded steel construction for longer life cycle and lower maintenance costs.

- Indoor and outdoor usage with serrated grip strut for slip resistance. Galvanizing is also available for outdoor applications.

- Modular components allow for countless customized configuration possibilities.

- Alternates include the Z-shaped, L-shaped and U-shaped configurations with intermediate land- ings where necessary.

- Ladders, ship ladders, OSHA stairs, and IBC stairs can be substituted or added between platforms depending on code requirements, available space and customer needs.

- Crossover systems can be custom designed to your specific application. Modular crossover sys- tems are also available with a maximum clearance of 8 ft., spans of 10 ft. in 2 ft. increments, and standard widths of 24 in., 30 in. and 36 in.

Dock Plates are rectangles of steel or aluminum with some type of locking leg and either hand hole or handles to move them. Plates are NEVER for power equipment. They are ideal for handtruck and pallet jack traffic … manually moved. They offer the lightest and most cost effective answer to your loading / unloading problem.

Dock Plates – A lot of time aluminum makes sense because of the lighter capacity and the need to manually move the dock plate. ONLY BLUFF builds dock plates that conform to the ANSI certification standard.

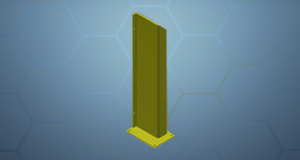

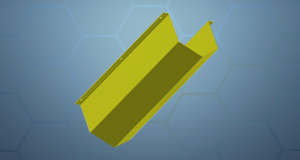

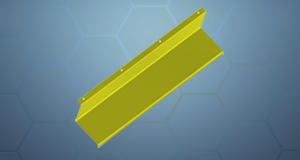

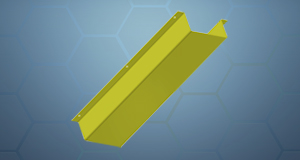

Bluff Manufacturing’s Door Guards are designed to protect overhead door tracks from damage, reducing overall maintenance costs. The tracks on your overhead door can be knocked out of service by a light tap from the forks of your lift truck. A pair of Bluff Door Track Guards installs for less than the price a service call to have them repaired. The finish is the super tough yellow powder coat. Safety products are available in four standard powder coat colors. Additional charges apply for custom powder coat colors and galvanized finish.

Features:- Chamfered edge reduces risk of hand injury when lowering door

- Wrap-around track design allows for free door operation

- Standard model projects 6″ from wall

- Anchors to both wall and floor

- Columns are 3/16″ thick steel

- Base plate is 1/2” thick steel with three 5/8” holes (fasteners not included)

- Powder coated safety yellow, with other standard colors available upon request

- Standard Safety Yellow durable powder coat finish.

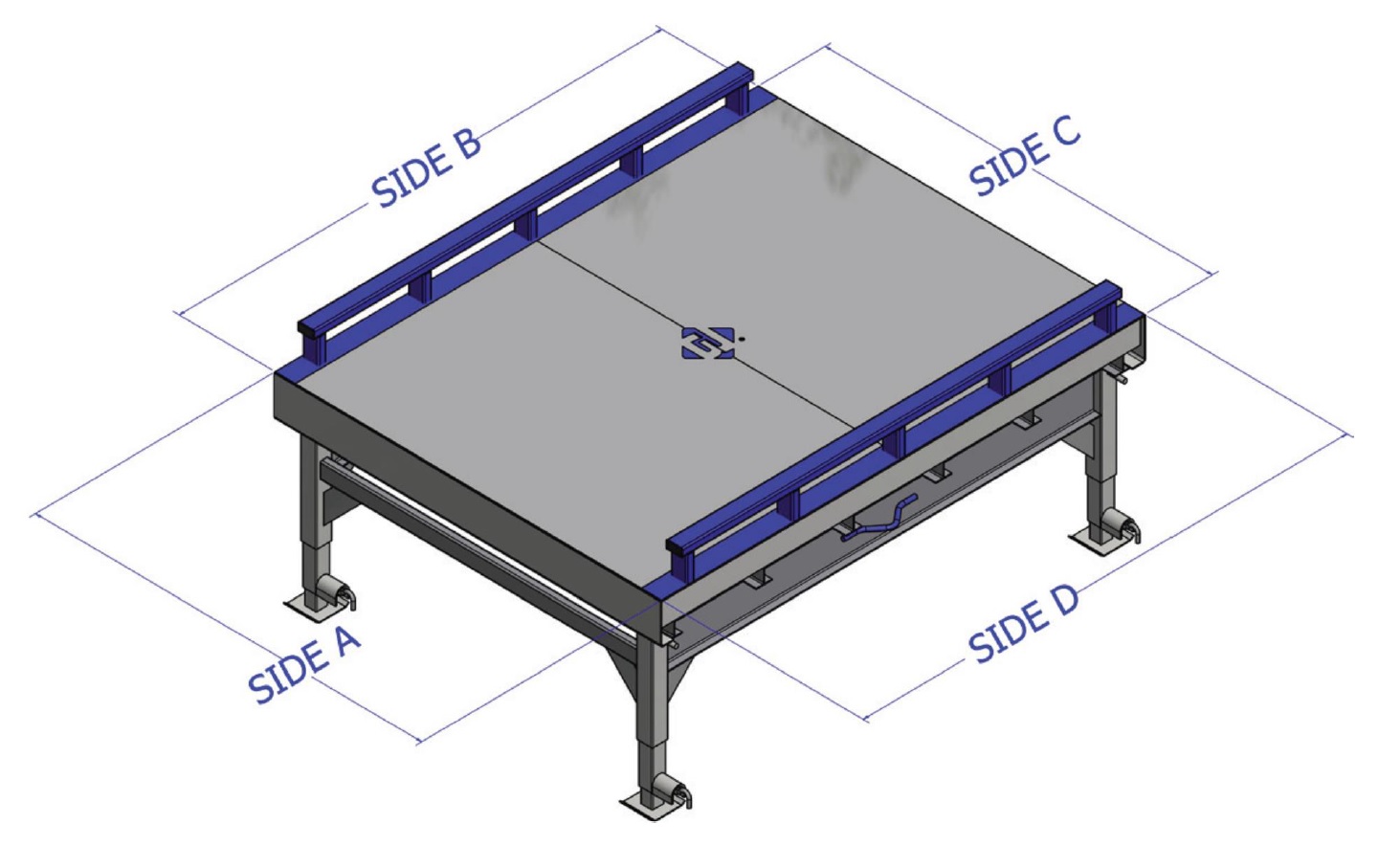

Safety Rails are designed for what you fear most when using forklift trucksentry into an area where there are people or other equipment and structures. While we can’t stop a speeding bullet we can stop a forklift truck at up to 10 mph. All measurements are center-to center of posts. Rails are 10 gauge formed steel with 5/8" steel plate base. Columns are structural steel beam. For special length rails, use next longer length for cost. Powder-Coated Safety Yellow. 5/8" Wedge Anchors and 1/2" Assembly Hardware provided.

Improve plant safety and efficiency with Bluff’s Tuff Guard safety rails. Safety rail systems work to protect personnel, machinery, building structures, in-plant offices, aisle ways, electrical panels, tool cribs, conveyors, finished products, receiving docks, cooling equipment and parking areas.

Benefits of safety railing include helping to reduce costs associated with employee injury and insurance claims, machinery downtime and building repairs due to accidental collisions. Bluff’s Tuff Guard safety railing is easily installed in a few minutes using basic hand tools and a concrete drill.

Features and Specifications

- Rated to withstand forklift impacts of up to 10,000 lbs at 6 mph

- Easy 4 bolt assembly – fasteners included

- ½” thick, 8”x8” steel baseplates – anchors included

- Plastic insert caps for post closure and enhanced appearance

- 10 gauge steel rails, 12” high x 2-5/8” deep – available in lengths from 1’ to 12’

- 4”x4”x3/16” structural steel tubing post – available in 18”, 30” or 42” height

- Options include: offset posts, lift-out rails and swing gates from 2’-6’ wide

- Powder coated safety yellow – other standard color options available upon request

Without expensive alternations to your dock, a Lo-Dock Leveler can be installed to effectively raise up a low dock anywhere from 3” to 20”. They can be easily installed onto any concrete dock – no welding required. Conforms to ANSI MH30.1 Standards.

Capacities from 20,000 to 30,000 lbs

Bumper and bumper blocks included

Worksheet required for proper design

Options include: door seals, runoff curbs, anchor kit, longer lip for refrigerated trucks, steel faced bumpers and hydraulic package.

Bluff Manufacturing’s pipe guards are designed to protect the multiple pipes, lines, and stacks that run along the inside or outside walls of a building. These vital lines circulate air, transport waste water, carry gas to heaters or to production equipment. Forklift trucks and other equipment used inside, outside or around your building can damage the lines and cause costly repairs. In all cases, it is important to prevent damage and keep them operational.

Bluff Manufacturing has been building pipe guards for several years and all pipe guards are built-to-order, ensuring the best fit for your needs. Pipe guard height and width specifications: They can be made to cover a 3” pipe or 8” pipe or anything in between; and can be 36” tall or 72” tall or any other height. Constructed of 3/16” smooth floor plate, this gives the impact resistance necessary to deflect forks from the forklift truck, a pickup or trailer backing into the building, or other damaging occurrences.

The pipe guards are powder coated yellow or any of the standard six colors offered by Bluff Manufacturing. This coating weathers well and maintains the like-new look for years of use. We are the industry expert on how to design the protection you need in your building or manufacturing facility.

Steel Platforms are a perfect solution for remote shipping docks (loading docks). Our heavy duty line of steel decked solutions start at 16,000 lbs. and go from there. Used one at a time or ganged for multiple dock positions, your shipping or receiving area can be enlarged quickly. 8" high curbs can be configured for your specific need. Portable Loading Docks, also known as Mobile Dock Platforms and Steel Platforms.

Features:

- Also available are adjustable legs for upgrade or replacement (sold separately in pairs).

- allow a forklift to make 90 degree turn into a truck and/or boxcar.

- Used primarily where space will not allow a standard Yard Ramp to be used.

-Portable Dock affords 90 degree turnability for safe forklift maneuvering.

- Portable Dock is a fast, economical way to expand your dock area

- Increase freight handling capabilities without the expense of site or concrete work.

Option:

Our Edge of Dock Leveler can be welded to your platform to make a complete loading dock solution

Doing the same job as Rack Guard this product is used to protect the intermediate uprights from damage from pallets or straddle truck outriggers. Available in different heights the yellow powder coat finish clearly defines the position of the upright for the driver so he can position his load.

Bluff Manufacturing’s Post Protectors are designed to Protect pallet rack uprights against damage from forklifts and pallet trucks. Like Rack Guard the Bluff Post Protectors can stop fork lift abuse to rack frame. A simple and inexpensive way to absorb the truck impact and head off the damage. The bright yellow powder coated steel product is available in 12" 18" and 24" high models. Three product thickness allow for just the right coverage for your rack. Seismic footplates available.

Features:- Steel thickness options: 1/4″, 3/8″, and 1/2″

- Standard heights options are 12″, 18″, and 24″

- Standard models fit around rack posts & footplates up to 4″ wide

- Custom oversize openings and protector heights available

- Base plates have four 9/16″ mounting holes (anchors not included)

- Powder coated safety yellow, with other standard colors available upon request

End of aisle on pallet rack is the most often damaged upright. A too tight turn with your forklift truck can cause damage to the upright and potentially collapse, causing product damage and injury. Bluff Rack Guard can prevent or lessen that damage and add a bright yellow warning to row ends or aisles

The ends of rows are always a problem in warehousing. A fork lift truck cutting the corner too closely can damage an upright at the minimum and at the maximum can harm product and even people. Bolting the heavy duty Bluff Rack Guard into place can stop the damage and the hazard before it becomes a problem. Powder coated yellow it is not only tough but adds a brightness to the warehouse that helps traffic flow.

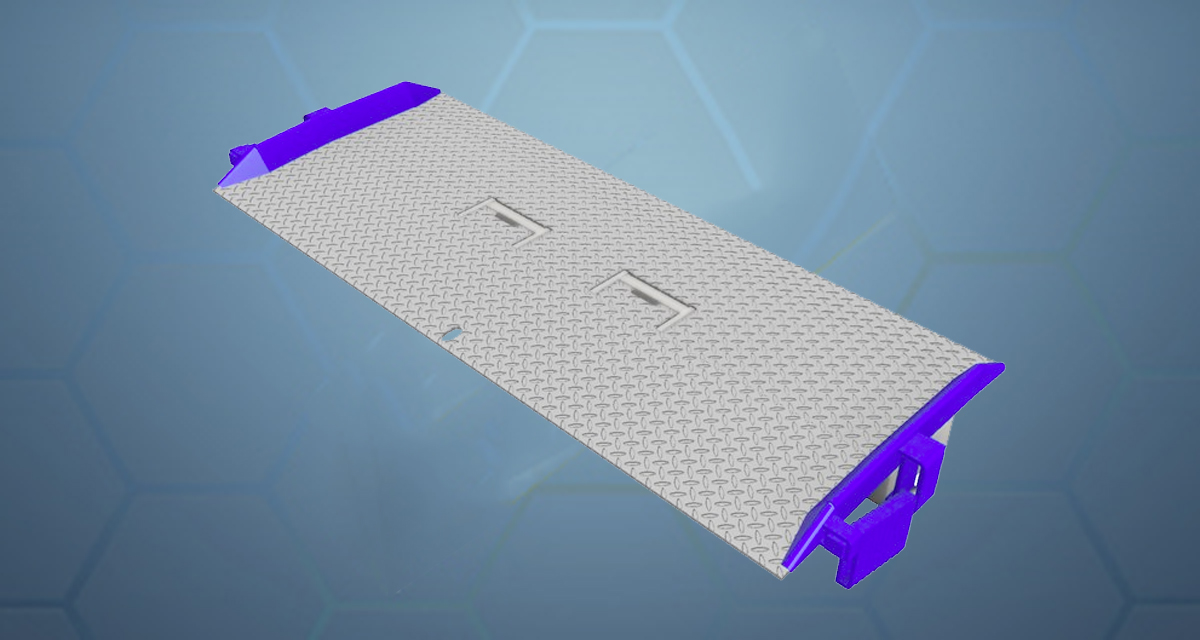

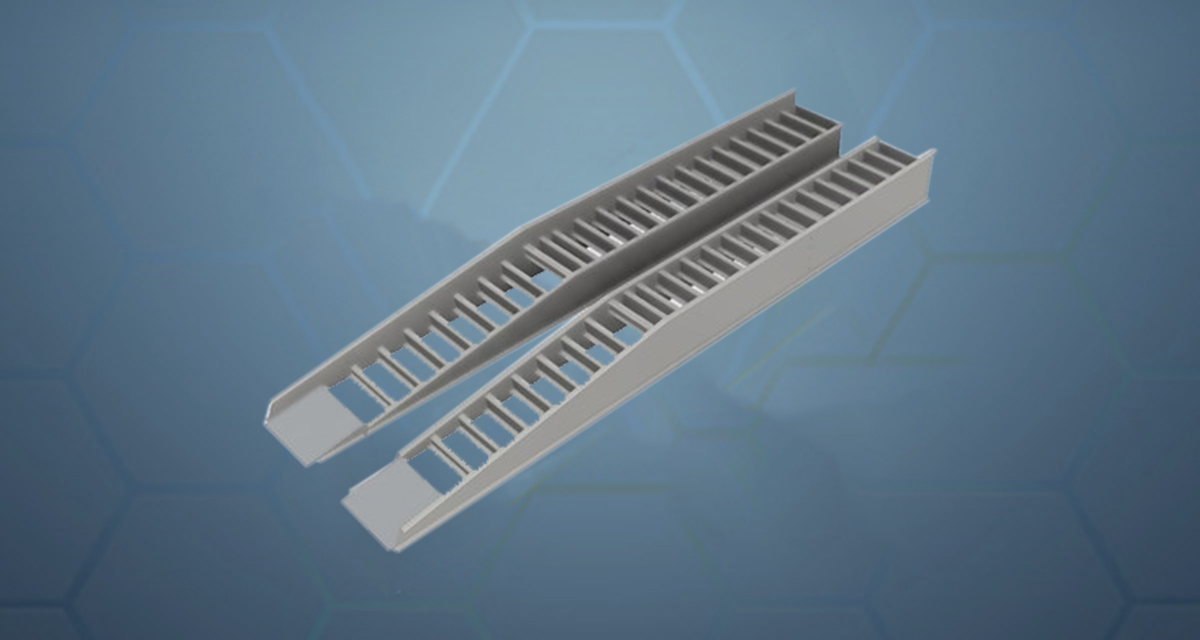

Portable steel railboards (rail boards) are a great solution to bridging the gap between railcars of all types and loading docks. Bluff Manufacturing has been manufacturing railboards for these applications for decades and it seems that no two rail sites are alike. Due to that fact, every railboard built is a custom fabrication for a specific site or set of conditions.

Rail Boards are designed for use on all types of railway boxcars, including refrigerated and special cars for the lumber and the paper industries. All rail boards are designed and built to match the specific dock conditions so each rail board is custom made to suit your individual specifications.

The Bluff railboard is easy to use. First position the rail board next to the railcar. The locking ring will automatically secure the railboard against the dock. Box understructure bumpers fit around the car latches to protect door latch.

Steel Rail Boards features include:

- Locking ring design

- Manufactured and tested in compliance with ANSI Standard MH30.2

- Fully welded steel rail boards provide a safe ramp for powered vehicle application.

- All-welded steel construction

- Capacities from 15,000 to 90,000 pounds

- Rectangular or flared design

- Box understructure for strength and safety

- Heavy-duty locking rings for safe, secure positioning

- Lifting loops drop into recessed pockets

- Lifting chains available

- Designed for use on all types of railway boxcars

- Designed and built to match the specific dock conditions

- Rail Board worksheet required. This information allows Bluff to manufacture a rail board that has the proper width, length, bends, capacity, and understructure for your application and safety.

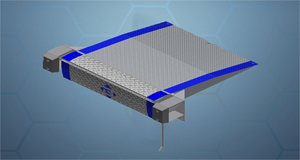

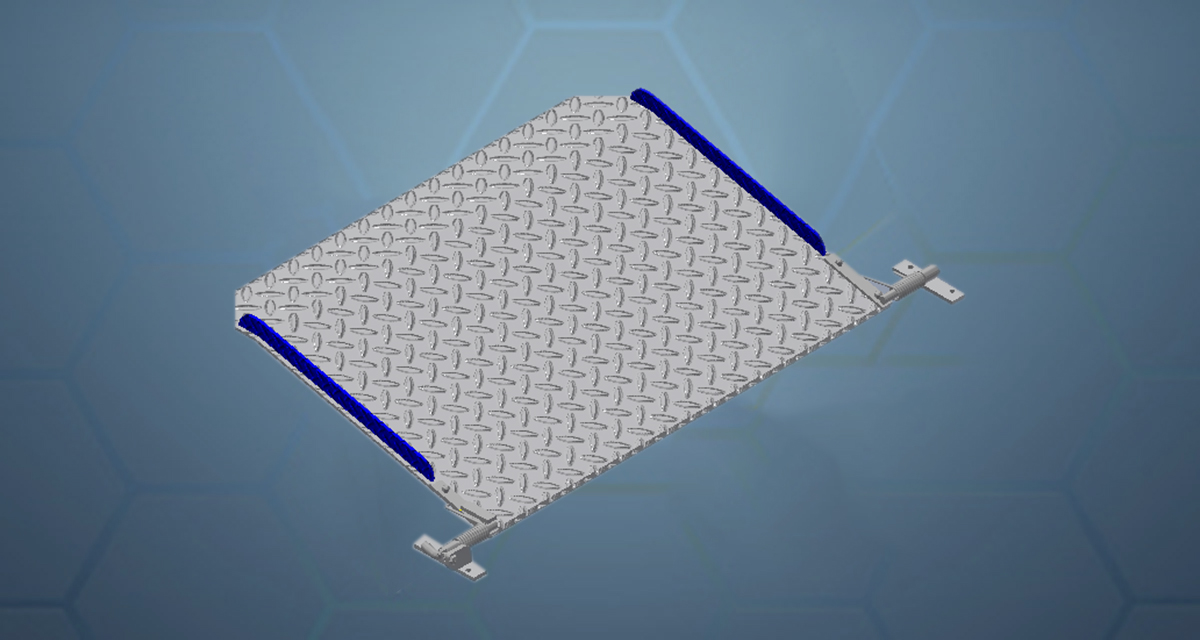

Bluff’s Spring Loaded Dock Plate (SL Plate) is an ideal solution for loading applications involving hand trucks and dollies, and is typically used by customers in the bakery, beverage and snack distribution industries. The SL Plate is vertically stored and is easily actuated by hand or foot. Available options include kick plate covers and traction tape. Not for use with powered equipment. Each SL Plate is site-specific and requires a completed worksheet to design. Manufacturing time 5 working days.

The SL Plate’s differentiating feature is its ability to be easily secured to the top of your dock, stored vertically and immediately available for use without the hassles of retrieval and/or placement.

Increase the operational efficiency and safety of your dock with a plate that is always in place and is always ready to use:

Reduce downtime in hunting for “misplaced” plate Avoid board damage from improper placement and retrieval Enhance dock safety by protecting against dock run off Increase efficiency

Fitted with a pair of spring loaded attachments, the diamond deck aluminum SL Plate can be lifted using less than 5 pounds of pressure and raised to the vertical position for storage. SL Plates are custom built for your unique dock needs taking into account plate size, bend specifications and spring weight. Recommended for loading applications involving hand trucks/dollies and pallet jacks (not for use with powered equipment) Vertically stored

Top-of-dock mounted unit with dual-spring lift assist Machine beveled deck edges allow for smooth transition Wide range of sizes available Capacities are size specific

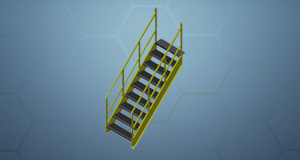

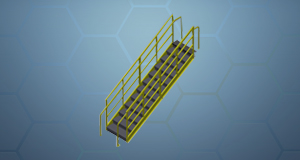

As a manufacturer of industrial stairs, ladders and landings, Bluff Manufacturing is your source for customized steel safe access products. From constructing mezzanine access for maintenance and daily operations to safely moving personnel across your conveyor line, we have the in-house manufacturing expertise and capacity required to deliver a solutions-based product with your individual specifications as our blueprint. You’ll find efficiency and quality for your budget point when you work with the Bluff Manufacturing professionals.

Industrial Stairs and Stairways

Bluff’s stairways are designed and manufactured to your particular application requirements. Our engineers employ code-compliant solutions to fulfill the details of your applications, including specific elevations, stairway lengths, and occupancy loads. Whether you need a new structure integrated into your existing system or a new, freestanding installation, all stairways feature a bolt-together design that ensures optimal strength and rigidity.

Stairway features include:

- Steel construction

- Standard three-part construction, including two stringers with welded handrail and griprail, and treads bolted between stringers

- Bar grate or diamond plate tread

- Closed or open risers

- Custom sizes and configurations (straight, L- and U-shaped runs with intermediate landings)

- Powder-coated components (black treads and safety yellow stringers)

- Easily integrated with landings, mezzanines, work platforms, conveyor crossovers, and towers

- All stairway structures are also designed and produced using the strictest compliance with existing UBC, IBC, and OSHA requirements for maximum safety, stability, and efficiency.

Steel Boards provides a safe ramp for heavy-duty loading applications.Our fully welded Steel Boards are designed to assist you in loading and unloading freight with a forklift at your loading dock. Our dockboards feature all-welded steel construction and capacities from 15,000 to 40,000 pounds.Selecting the proper board product for your application will improve product life, safety, and loading efficiency. Review the Board Selection Guide on the back page prior to ordering to ensure your product selection is correct. All steel boards below are manufactured and tested in compliance with ANSI Standard MH30.2.

Steel Boards Boards are designed for use on all types of railway boxcars, including refrigerated and special cars for the lumber and the paper industries. All boards are designed and built to match the specific dock conditions so each rail board is custom made to suit your individual specifications.The Bluff board is easy to use. First position the board next to the railcar. The locking ring will automatically secure the railboard against the dock. Box understructure bumpers fit around the car latches to protect door latch.

Truck Risers close the vertical gap between a truck bed and dock floor, which not only contributes to ease of loading and unloading, but ensures that it can be done in a safe manner.

Dock equipment such as dock boards, plates or levelers can be easily damaged during loading and unloading if a truck is not properly positioned at dock height. Truck Risers remedy this problem by meeting the dock height, while also creating a level transition between the truck and dock. The safety of your employees and equipment are increased with this simple and cost effective solution.

Sturdy steel construction

A set of risers can handle 40,000 lbs per axle / 80,000 lbs per pair

Heights from 6”-24” allow you to raise a variety of trucks up to meet dock height

Each riser is 42” wide, making them easy to position for any application

6” runoff curbs serve as runoff/ fall protection

Includes holes for anchoring

Made in the USA

Wheel risers allow trucks and semi trailers to be positioned properly above loading docks for more efficient loading and unloading of freight. Widths of 18″ and 24″. Lengths to accommodate both single, dual, or tandem axle trailers. Wheel risers can be portable or permanently positioned. Custom sizes available.

Wheel Risers Eliminate unsafe, below dock loading conditions Wheel Risers Reduce damage to loading dock equipment Heights up to 12″wheel risers

Completion of this worksheet at the time of the order will allow us to specify the exact size, length and capacity to provide you the most effective unit for your situation. We will be able to quote you an exact price and delivery time, usually within 24 hours.

Wheel risers can be portable or permanently positioned. Custom sizes available.

Wheel Risers Eliminate unsafe, below dock loading conditions Wheel Risers Reduce damage to loading dock equipment Heights up to 12"wheel risers

STEEL AND ALUMINUM WHEEL RISERS- Eliminate unsafe, below dock loading conditions

- Allow trailers to be positioned properly above dock for more efficient loading

- Reduce damage to loading equipment

- Heights up to 12"

- Widths of 18" and 24"

- Lengths to accommodate single, dual, or tandem axle trailers

- Custom sizes availables

- Portable or permanently positioned

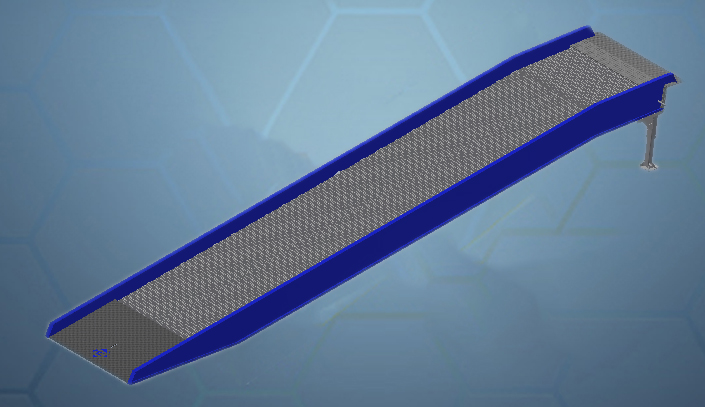

Yard Ramps, also called Portable Loading Ramps or Portable Loading Docks, are a safe and cost effective answer to many loading dock issues. Bluff Manufacturing has more experience and has built more yard ramps than anyone, by far. Our standard design translates into a custom solution that is quickly delivered to your job site and lasts for many years.

Touch up paint for Yard Ramps:

Rust-oleum 249114 Gloss Deep Blue (Painterís Touch line)

Rust-oleum 7786 Smoke Gray

Yard Ramp Applications

Most yard ramps perform one of two functions. They allow traffic from the ground up into a truck bed or from the dock level down to the ground. Which of these jobs you choose to do will dictate which of the designs will be most appropriate for your application.

Dock-to-Ground Stationary Yard Ramps

Dock-to-ground and back, normally indicates that either a vehicle or forklift needs to be moved back and forth. If the dock is in the 39? to 60?+ range then a 30' all incline yard ramp is the choice that makes the most sense. A width that allows for the equipment plus some manuevering room and a decision about a few accessories and you have a perfect solution for your loading dock. Our most popular yard ramp model for this application is our 16SYS7030NU (the NU stands for no undercarriageÖif you donít need to move the yard ramp you can save the money).

Ground-to-Truck Portable Yard Ramps

Ground-to-truck has the same decision elements plus the need for a level off zone at the top before your load enters or leaves the truck. The length of this level off is dictated by your truck and load length (the most popular length is 6'). When you apply a capacity requirement of three times forklift truck capacity and a couple of accessory decisions your perfect solution becomes clear. We find that our 16SYS8436L model yard ramp is our most popular.